HOT SALE ABB 261GC 261GCLRAEFSS21-MS Gauge and Absolute transmitters with direct mount seal Brand New with Good Discount

- Product description

- Contact us

ABB 261GC 261GCLRAEFSS21-MS Gauge and Absolute transmitters with direct mount seal

General description

For the transmitters 261Gx and 261Ax, process connections with flush diaphragms are available in a variety of designs

and dimensions to meet the requirements of a wide range of sectors, including industries such as oil and gas, paper,

chemicals, food and pharmaceuticals.

NOTE

The measuring range lower limit (LRL) for model 261A is 0 absolute for all measuring ranges. Special filling fluids are available for applications with high

temperatures. For hygienic applications or use in the food industry, select filling fluids that are classified by the US Food and Drug

Administration (FDA) as safe for use with food.

Span limits

Maximum span = measuring range upper limit (URL)

To optimize performance characteristics, it is

recommended that you select the transmitter sensor code

with the lowest turn down ratio.

TURNDOWN = Upper range limit/set span

Damping

Configurable time constant between 0 and 60 s.

This is in addition to the sensor response time, and can be

adjusted via the optional LCD indicator, handheld

terminal, or PC user interface.

Warm-up time

Ready for operation as per specifications in less than 10 s

with minimum damping.

Insulation resistance

>100 MΩ at 500 V DC (between terminals and ground)

Zero suppression and elevation

The zero position and span can be set to any value within

the measuring range limits listed in the table if:

— Set span ≥ minimum span

Technical specification

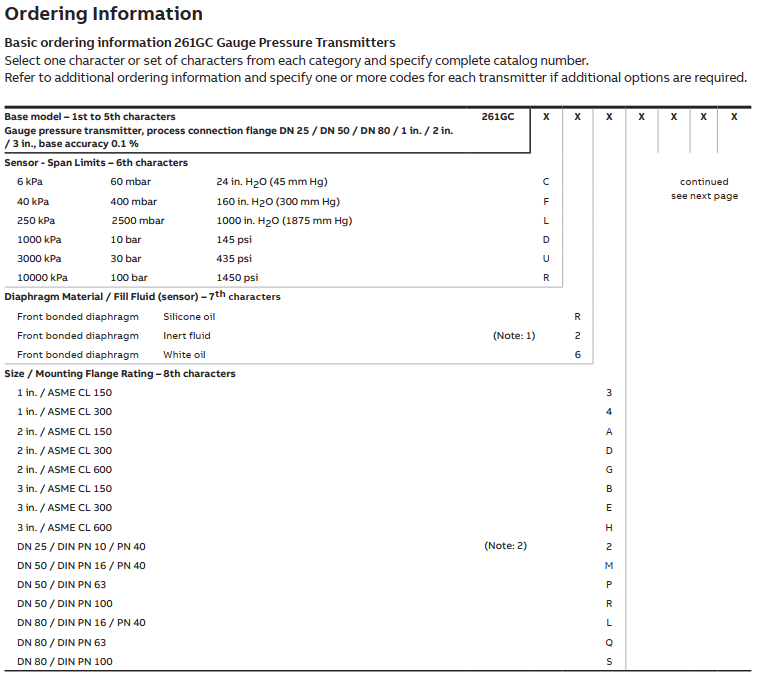

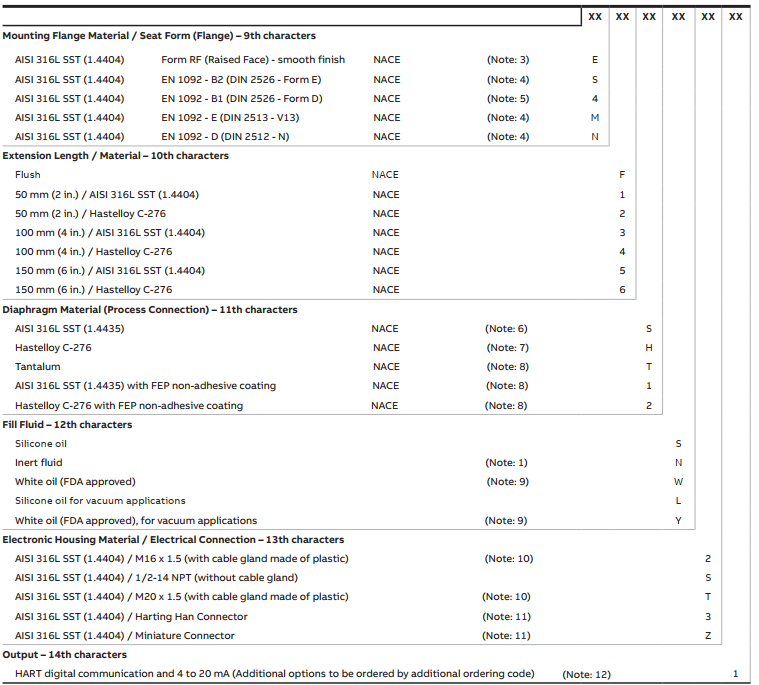

(Please refer to the order information to check the availability of different versions of the relevant model)

Materials

Separation diaphragms1

See order information

Process connection1

See order information

Filling fluid for process connection

See order information

Sensor filling fluid

Silicone oil, inert filling (carbon fluoride), white oil (FDA)

Mounting bracket

Stainless steel

Sensor housing, electronics housing and cover

Stainless steel (1.4404 / 316L)

Filter for atmospheric ventilation

Filter housing: Plastic (standard), stainless steel

(code EA, AB)

Filter material: Polyamide (PA)

Viewing window in cover (LCD display)

Polycarbonate, Makrolon 6557

Cover O-ring

EPDM

Name plate

Plastic data plate attached to the electronics housing

Calibration

Standard: 0 to upper range limit (URL)

Optional: To specified measuring span

(1) Transmitter parts that come into contact with fluid

Optional extras

LCD display

Can be rotated in 90° increments into 4 positions

Additional tag plates

Code I2: For measuring point tag (up to 30 characters)

and calibration specifications (up to 30 characters: lower

and upper value plus unit), attached to transmitter

housing.

Code I1: For customer data (4 lines with 30 characters

each), attached to transmitter housing with wire.

Cleaning stage for oxygen applications (O2)

Certificates (test, design, characteristics, material

traceability )

Name plate and operating instruction language

Process connections

See order information.

Electrical connections

M16 x 1.5 tap hole with cable gland (cable diameter

approx. 5 to 10 mm), directly on housing

or

M20 x 1.5 (via adapter) with cable gland (cable diameter

approx. 6 to 11 mm)

or

1/2-14 NPT (via adapter) without cable gland

or

Harting Han plug connector (with mating plug (socket

outlet, for wire diameters of 0.75 to 1 mm2 and cable

diameters of 5 to 11 mm))

or

Miniature plug connector (without mating plug (socket

outlet))

Terminals

HART version:

Two connections for signal / auxiliary power, for wire

cross-sections from 0.5 to 1.5 mm2 (16 AWG)

Grounding (optional)

External ground terminals for wire cross-sections up to

4 mm2 (12 AWG).

Weight

(without options)

• Approx. 0.7 kg (1.54 lb)

• Additional 650 g (1.5 lb)

Packaging

Carton with dimensions of approx. 240 x 140 x 190 mm (9.45 x 5.51 x 7.48 in.)

Model No Example

261GCLRAEFSS21

261GSRKBNT1EHL1AAABB2P1M5

261GCLRAEFSS21-MS